For High-speed applications

SPOOLWINDER SW6-14

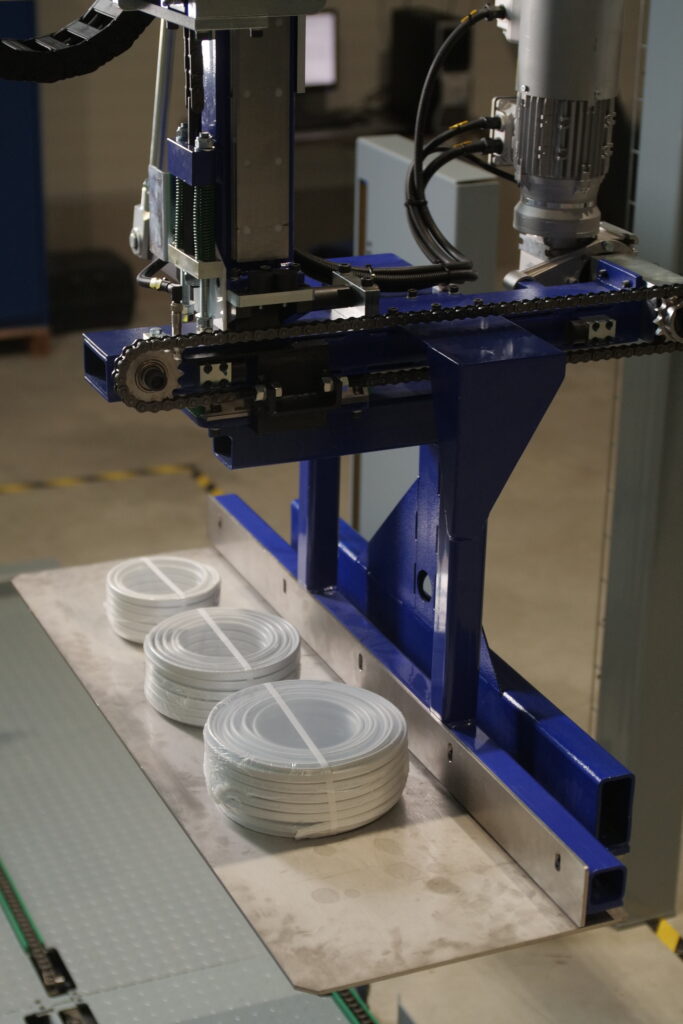

Request the product catalogueOur advanced system features a Dual-head Spooler, expertly engineered for high-speed operations and handling of THHN, single conductor wire and NM and multicore conductors.

Features

- Servo-Driven Stretch Wrap: Efficient stretch wrapping system with servo precision and seamless refill.

- Auto Spool Handling: Automated loading and unloading for ease of use.

- Fast Size Transition: Rapid changeover for different product sizes.

- Accurate Winding: Precision winding and tension control for quality results.

- User-Friendly Design: Safe and ergonomic for operator comfort.

Additional Options

To further enhance your production capabilities, that machine can be equipped with a variety of additional options, tailoring them to your specific manufacturing needs:

- Driven Payoffs

- Extrusion inline integration with additional features

- Laser Length Counter

- Cable Test Equipment – Spark tester, Lump & Neck detector

- Accumulators & Dancers

- Kick-out station for faulty spools

- Streamer tape unit

- Spool in a Box – Complete line solution

- CE/SP Case Erector and Packer

- Label Applicator

- Palletizers

- Semi-Automatic Pallet wrapper

- ERP integration

- Industry 4.0 integration

Specifications

- Spool OD: 165 mm – 360 mm (6.5”- 14”)

- Cable diameter: 2,3 mm – 8 mm (1 mm2 – 16 mm2) (0.09″- 0.32″ (AWG 18 – AWG 6))

- Spool Width: 90 mm – 300 mm (3.5”- 12”)

- Max Spool Weight: 56 Kg (125 lbs.)

Speed and output depend on your application.

Elevate Your Operations: Exceptional

Equipment Benefits

Fully Automatic Spool Packaging System:

Designed for efficient and automatic packaging of spools into boxes with labeling and palletizing.

Swift Stop Time:

Features a reliable Cut & Catch mechanism ensuring a minimized stop time for highest possible output.

Center Lift Option:

Tailored to meet the needs of a fast-paced production environment.

Automated Loading and Unloading:

Ensures quick and effortless handling of spools, with stretch wrap securing the outer ends.

Spool Size Range:

Specially designed for precise packaging of cable and wire products on spools with a diameter of 165mm to 360mm (6.5”- 14“).

Recipe-Based Operational Control:

Efficiently minimizes downtime and accelerates product and spool changeovers, ideal for the high-speed settings.

The compact and versatile design allows for operation of both OFFLINE, using a driven Payoff or Flyer and INLINE with an extruder.

The compact and versatile design allows for operation of both OFFLINE, using a driven Payoff or Flyer and INLINE with an extruder.

Compatible Equipment

Payoffs and Take-ups – UW – OW10/12/16/22/26/30

Tire Driven Shaft-less Portal Type Design: Ideal for high-speed coiling, spooling operations, rewind lines, or dual take-up systems.

Accumulators

Windak Group specializes in both vertical and horizontal accumulator designs, providing versatile solutions for various production lines.

Dancers

Windak Group has a rich history of developing, constructing, and supplying a diverse range of dancers- gravity, pneumatic and servo driven types.

Length Counters

Windak length counters are equipped with adjustable horizontal and vertical guide rollers, ensuring precise measurements.

Palletizer GMC-BB

The GMC-BB, a 4-axis box palletizer, is designed to operate both as a stand-alone unit and in combination with a spooler or coiler.

Palletizer GMC-CBC

The GMC-CBC is a palletizer that comes in both 3-axis and 4-axis options.

Palletizer GMC-RBR

Designed for versatility, the GMC-RBR, a 2-axis palletizer, works as a standalone unit or in combination with a coiler or spooler.

Palletizer GMC-SBS

The GMC-SBS is a palletizer that comes in both 2-axis and 3-axis options.

Additional Equipment

Our advanced technology ensures seamless quality control in unmanned, fully automatic operations.